The safety of your favorite foods benefits from SQF audits and the measures manufacturers take to ensure safe food supplies–such as through independent testing of their compressed air.

On January 6, the Safe Quality Food Institute (SQFI) announced the incorporation of an unannounced audit protocol to be included in the next revision of the SQF Code (SQF). This means SQF will become the first internationally accredited third-party assessment program to require unannounced audits.

In a statement, Robert Garfield, senior vice president, SQFI, noted that the program update will be introduced in February 2014 and implemented in July 2014. One out of every three SQF audits will be unannounced.

“We made the decision to enhance the rigor of the SQFI program after consulting with numerous stakeholders,” said Garfield. “We understand that the food industry must respond to and meet the nation’s food safety challenges more rapidly and effectively, which requires a more nimble approach to our program.”

ABOUT SQF & COMPRESSED AIR

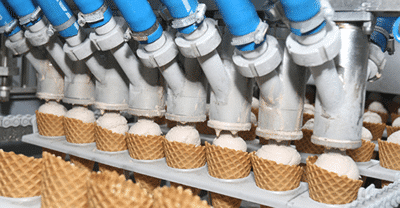

SQF Compressed air purity is essential to many manufacturing, food processing, bottling and packaging operations. High-quality compressed air provides energy for pneumatic conveyer and handling systems that transport liquids and powders during the production cycle. Compressed air influences the safety of wrapping, sealing, labeling and palletizing these products for shipping or storage. SQF Compressed Air Purity is critical for providing food products and packaging that are not only cost effective to process but safe to eat or drink.

Food & Beverage companies utilize TRI Air Testing’s kits to collect compressed air samples. Results on nearly all standard tests are available within 24 hours of the kit’s return to TRI. Secure, round-the-clock, online access to reports ensures the most timely delivery of results possible.

The Food and Beverage manufacturing industry can apply principles of the HACCP (Hazard Analysis and Critical Control Point) system and a risk analysis. The seven HACCP principles are included in the international standard ISO 22000 Food Safety Management System (FSMS). This standard is a food safety and quality management system incorporating the elements of prerequisite programs (GMP & SSOP), HACCP and the quality management system, which together form an organization’s Total Quality Management system. For FDA regulated operations in the United States, HACCP compliance is currently regulated by 21 CFR part 120 & 123. Additional food safety resources include the Global Food Safety Initiative (GFSI), International Organization for Standardization (ISO), British Compressed Air Society Limited (BCAS), Food Safety Modernization Act (FSMA), Canadian Food Inspection Agency (CFIA) and the Safe Quality Food Program (SQF). The SQF Code states that compressed air used in the manufacturing process shall be clean and present no risk to food safety and compressed air used in the manufacturing process shall be regularly monitored for purity.

Compressed air is a Critical Control Point (CCP) and includes direct contact or indirect contact with a food or beverage product. TRI Air Testing suggests performing a baseline, no specification comparison, testing on new or untested systems to help determine the appropriate specification requirements. We can also provide compressed air purity for your own custom specifications.

Food, beverage and packaging facilities must develop a careful understanding of their products and testing protocol to ensure the compressed air that is critical to their food manufacturing operations is used consistently and responsibly.

TRI Air Testing provides independent laboratory support for many food, beverage and packaging companies. We offer 24-hour turnaround time and online laboratory reports via MYAIR . SQF Managers use compressed air testing equipment provided by TRI to collect compressed air samples as part of their facilities’ air quality compliance, safety and SQF food safety programs.