LDS Hospital, Salt Lake City, Utah, is one of the main facilities that utilizes Intermountain Healthcare’s Hyperbaric Medicine capability.

The medical field is a major user of compressed air. The pharmaceutical industry utilizes compressed air in manufacturing and packaging, much as the medical device manufacturing industry does. But the manufacturing side is not where it ends. Hospitals, clinics and other healthcare facilities are deeply linked to compressed air usage for improving patient and personnel safety and comfort and for providing precision control of care. Further, the role of air and gas extends well beyond compressed air. Medical facilities are also precise in their air and gas quality, piping purity, gas concentrations, and much more.

Here, we interview Intermountain Healthcare’s James Bell, CHT, EMT about one of the most intriguing ways air and gas (including compressed) is used in his work: hyperbaric medicine.

Bell is the Technical Supervisor – Hypobaric & Hyperbaric Safety for Intermountain Healthcare and LDS Hospital (Salt Lake City, Utah). Intermountain Healthcare is an internationally-recognized, nonprofit system of 22 hospitals, 185 physician clinics, 33,000 employees and affiliated health insurance company (SelectHealth) serving the populations of Utah and southeastern Idaho. They provide a large range of healthcare services, from basic care (e.g., flu vaccinations) through state-of-the-art cancer treatment.

What is the focus of your work?

Intermountain Healthcare offers a full range of services, from urgent care to the region’s most advanced trauma centers. Hyperbaric medicine is one of those services and the department I am employed with.

Intermountain Healthcare currently has five facilities that provide hyperbaric oxygen (HBO2). Our department operates out of two of those hospitals, LDS Hospital in Salt Lake City and Intermountain Medical Center in Murray, Utah. Intermountain Healthcare is an internationally recognized, nonprofit system of 22 hospitals, a Medical Group with more than 185 physician clinics, and an affiliated health insurance company, SelectHealth. Our 33,000 employees serve patients and plan members in Utah and southeastern Idaho. Whether you need a flu vaccination or the latest in cancer treatment, we offer a full range of services, from urgent care to home care to the region’s most advanced trauma centers. Providing excellent care of the highest quality at an affordable cost is at the heart of our mission.HBO2 therapy is a unique treatment approach for certain infections, poisoning and complicated wounds. During HBO2, patients are given 100% oxygen at pressures two to three times greater than that at normal sea level.

LDS Hospital’s hyperbaric service uses monoplace (single person) hyperbaric chambers made of clear acrylic to administer this high oxygen dose. When a patient breathes 100% oxygen under pressure , greater amounts of oxygen are dissolved into the bloodstream and delivered to the body tissues in amounts sufficient to promote healing. The benefit comes from the breathing of the oxygen under pressure, not from the oxygen being in direct contact with the skin or wound. The pressure used and the number of hyperbaric sessions depends on the problem being treated.

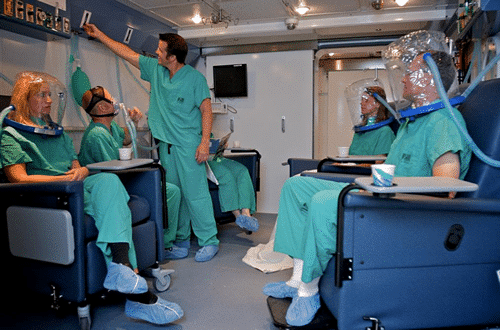

Intermountain Medical Center’s hyperbaric medicine service offers specialized treatment to patients with chronic wounds, tissue damage from radiation, and certain infections, as well as for emergency conditions such as carbon monoxide poisoning, diving accidents, and gas embolism. The department’s walk-in, 26-ton chamber is ideal for outpatients and can treat up to 8 individuals at a time. Patients who are critically ill and need extensive medical support can be treated in a single-person hyperbaric chamber inside the ICU.

How do you utilize compressed air?

The monoplace chambers are normally pressurized with oxygen but can be compressed with compressed air. The multiplace chamber is pressurized with compressed air. At both LDS Hospital and Intermountain Medical Center we are using the hospital’s low pressure medical air compressors for the air to compress the chambers with. We also utilize high pressure (HP) cylinders of United States Pharmacopeia (USP) medical air for both types of chambers as required by the National Fire Protection Association (NFPA ) 99 Health Care Facilities Code, 2012 edition; 14.2.4.1.3 and 14.2.4.1.3, requires an alternative source of breathing air that is independent of the chamber atmosphere, for all occupants of the chamber(s) in case the chamber atmosphere is fouled. We also provide USP medical air to patients as part of their therapy to prevent oxygen toxicity or as part of a study where the sham might be breathing air instead of oxygen. Learn more about TRI Air medical air testing services.

Intermountain Medical Center, Murray, Utah, utilizes hyperbaric medicine. The facility was voted #1 in Utah in U.S. News and World Report’s Best Hospitals in America Rankings for 2013-2014

What are the standards/guidelines you test for?

The primary standard in use is the NFPA 99 Health Care Facilities Code, 2012 edition, chapter 14. The medical air compressors are continuously monitored for Dew point and Carbon Monoxide (CO) as required in chapter 5. Our hyperbaric department completes quarterly sampling of the medical air from the compressors and high pressure cylinders to meet The Compressed Gas Association (CGA) grade N which is the standard used for USP medical air. The NFPA 99 14.2.8.6.1 requires that we test the air from the compressors bi-annually and after major repair or modifications. We have chosen to do this quarterly for all of our medical gas not just the air from the compressors. Our hyperbaric departments are accredited by the Undersea and Hyperbaric Medical Society Facility Accreditation program which expects that we verify the purity of the gas supplied to patients and staff in the chambers. Whether it is required or not it is good practice to verify the purity of gas supplied to patients and staff.

Compressed air standards/guidelines are rarely applicable in full for a facility. Are there any particular levels of air quality you have found to be optimal for your current operations’ safety and efficiency?

NFPA 99, 14.2.8.6 and 14.2.8.6.3 requires that the air supplied from compressors meet a minimum of CGA grade E for multiplace chambers. There is an additional limit of no condensable hydrocarbons for air supplied to the monoplace chambers. If the air is shared with the hospital and not dedicated to the hyperbaric service, we must meet 14.2.4.6 which is the requirements of 5.1.3.6.3, chapter 5 and chapter 14. At LDS hospital and Intermountain Medical Center, the medical air compressors are shared and we test to meet NFPA chapter 5 for medical air from compressors and CGA Grade N.

NFPA 99, 14.2.8.6.4 and 14.2.8.6.5 requires that the air or oxygen from cylinders must meet USP medical air and oxygen standards.

**

PROFILE: INTERMOUNTAIN HEALTHCARE

Intermountain Healthcare is an internationally recognized, nonprofit system of 22 hospitals, a Medical Group with more than 185 physician clinics, and an affiliated health insurance company, SelectHealth. Our 33,000 employees serve patients and plan members in Utah and southeastern Idaho. Whether you need a flu vaccination or the latest in cancer treatment, we offer a full range of services, from urgent care to home care to the region’s most advanced trauma centers. Providing excellent care of the highest quality at an affordable cost is at the heart of our mission.

Intermountain Medical Center is the premier tertiary medical campus in the Intermountain West with centers of excellence in cardiovascular medicine, cancer care, outpatient care, women’s and newborn care, Level 1 trauma and emergency medicine, and pulmonary care. Intermountain Medical Center serves as the flagship medical facility for the Intermountain Healthcare system. The three components of Intermountain Medical Center’s mission – the science of medicine, the spirit of caring, and the miracle of healing – are delivered in state-of-the-art facilities surrounded by an environment of beauty on a 100-acre campus in the heart of the Salt Lake Valley.

**

TRI Air Testing thanks James Bell and Jess Gomez (media relations) at Intermountain Healthcare for sharing their time and expertise.

TRI, a proud member of NFPA and MGPHO, provides compressed air testing with excellence in quality and science.