While automotive design (exterior and interior) and performance are the hallmarks of any manufacturer’s brands, one of the essential draws for the customer is the personal attachment they may feel towards color. Sharp colors are featured on many high-performance sports cars. Executive blacks and grays are found on many luxury vehicles. And most manufacturers offer boutique colors specific to certain of their models. No matter the size and make of a vehicle or how fast it gets from 0 to 60, automotive paint plays a key role in this vital industry.

Safety is also essential, and not just for the drivers and passengers of a car. Automotive manufacturers are dedicated to protecting their workers in the manufacturing process. Proper management and monitoring of compressed air equipment and breathing air apparatuses are essential to ensuring safe operations.

Safety is also essential, and not just for the drivers and passengers of a car. Automotive manufacturers are dedicated to protecting their workers in the manufacturing process. Proper management and monitoring of compressed air equipment and breathing air apparatuses are essential to ensuring safe operations.

On the paint side of the business, manufacturers are closely tied to Grade D/OSHA regulations. This involves safe breathing air for the protection of workers. Air testing is essential to maximizing the safety of this class protective gear.

Every manufacturer (e.g., Toyota, GM, VW, Hyundai-Kia, Ford, Nissan, etc.) ensures the safety of its workers throughout the production process. One of the many common safety measures is the use of respirators and other breathing protection gear.

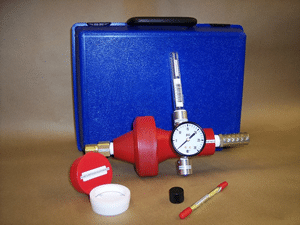

TRI Air Testing’s sampling kits have been used by numerous top automotive manufacturers to help them meet or exceed CGA Grade D or OSHA 1910.134 requirements.

View a sample compressed air report here (PDF).

TRI Air Testing’s sampling kits have been used by numerous top automotive and aircraft manufacturers to help them meet or exceed CGA Grade D or OSHA 1910.134 requirements.

The aircraft manufacturing industry, like the automotive industry, is also dedicated to protecting the safety of its workers through proper maintenance and testing of breathing air apparatuses. Major aircraft manufacturers around the world test and evaluate breathing air samples regularly to ensure their employees’ health and safety.

Whether you travel by road or through the skies, part of your journey is inevitably linked to compressed air and breathing air sampling and safety.