Maintaining Air Purity in Food & Beverage

The Original Compressed Air and Pure Gas Testing Laboratory

Food & Beverage Industry

Compressed air purity is essential to many manufacturing facilities in food processing, bottling and packaging operations. High-quality compressed air provides energy for pneumatic conveyer and handling systems that transport liquids and powders during the production cycle. Compressed air, ambient air and pure gas delivery systems influence the safety of wrapping, sealing, labeling and palletizing these products for shipping or storage. It’s important to know regulatory changes require compressed air and pure gas testing. SQF, BRC, GFSI, and FSMA all mandate testing of compressed air systems that come directly or indirectly into contact with products.

This is why TRI Air Testing provides independent laboratory support for many food, beverage and packaging companies with compressed air and pure gas testing services. F&B manufacturing managers use compressed air testing equipment provided by TRI to collect compressed air samples as part of their facilities’ air quality compliance and food safety programs. The process is easy. TRI Air Testing ships the testing kit out to a facility, where the sample is taken and then sent back to the TRI Air Testing lab for results. TRI Air Testing also provides on-site support if needed.

Importance of Mold and Bacteria Testing

In addition, mold and bacteria testing is available for F&B compressed air, ambient air and pure gas delivery systems and recommended multiple times per year. It is important to keep air compressed systems clean of possible harmful bacteria that can affect food production. TRI Air Testing methodology is supported by ISO 17025:2017-accredited expert partners. Contact us for help in guiding facilities toward which ambient procedure is right based on compliance.

Here is a breakdown of the credentials and qualifications of the TRI Air Testing program that applies to all F&B manufacturing facilities:

- ISO 17025:2017 Accredited by AIHA-LAP, LLC

- Compliant to ANSI/ISO/ASQ 9001:2015

- HACCP and PCQI Certified Staff

- Wide Range Testing of Custom Specs and Programs Based on Industry

Air and Pure Gas Testing in Your Food Facility Webinar

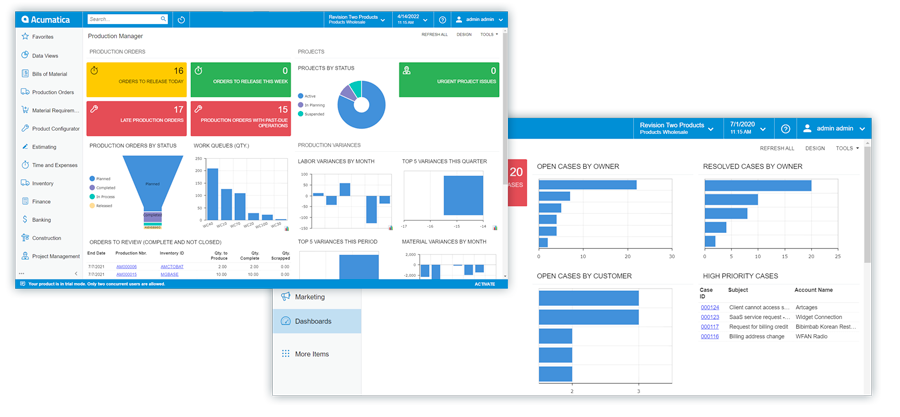

Air and pure gas testing in your food facility is mandatory in the SQF benchmarked standard for some of the categories. We discuss what is required, how it is conducted and what you need to know when an auditor is auditing your facility’s documentation concerning the air and pure gas testing.

Our Services

First-Time Clients:

- Consultation with our team to understand your specific needs

- Recommend specific tests suited for your facility

- Walk through the test results with you and your team

Ongoing Services:

We provide international standards and methods for sampling and the testing of compressed air, ambient air and pure gas delivery systems. This includes a multitude of pure gas types up to Five 9’s purity. Additionally, we collect mold & bacteria samples for testing in compressed, ambient, and pure gasses.

- Team of analysts and scientists

- On-site testing

- Affordable testing kits and 24-hour turnaround time

- Provided training videos on how to collect test samples

Do you need help?

We are happy to provide your company with a no cost consultation call to help you assess your testing needs. Our employees are air and pure gas testing experts as well as HACCP and PCQI certified.

FAQ

Regulatory Compliance: SQF, BRC, GFSI, and FSMA all mandate testing of compressed air systems that come directly or indirectly into contact with your product.

Yes. Our test kits are user-friendly and our support specialists are available to guide you through the process if you need assistance.

Reports are delivered within 1 business day of receiving air samples with no additional fees.

No. Some facilities choose to purchase their own, but we have all the necessary equipment at our testing facility.

If your air samples come back with results that need to be addressed, our team will walk you through the next steps which may entail an on-site visit for additional in-depth testing.

AIR AND PURE GAS TESTING ALSO AVAILABLE FOR: